The first step in making a jacket is a digital illustration, drawing a pattern from an illustration. In this step, we’ll create our patterns for each jacket part.

We can use existing patterns or create new ones for each piece by hand-drawing them on paper or with digital software.

After digital illustration, the second most important part is cutting out pieces from cardboard and sewing them together into various parts of our garment, such as sleeves and cuffs.

This process allows us at The Jacket Place an online leather jacket store and to make sure that every aspect of our products is perfect before going into the production stages!

The pattern is the key to the fit of our garment. It must be drafted to the right size, shape, and style.

Drafting is done with a paper template called a muslin or mockup.

This helps ensure accuracy in cutting and sewing techniques because it allows us to see how the final product will look.

After, we start cutting materials into pieces that fit together perfectly like puzzle pieces do when put together by hand crafting abilities alone without any machines involved whatsoever.

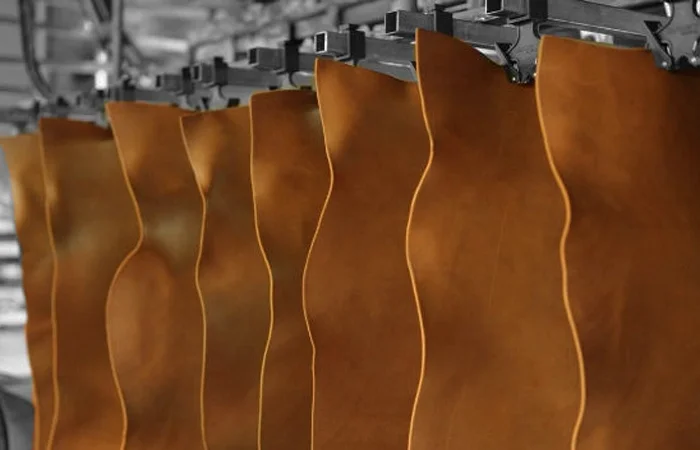

Leather is a natural product that has been used for centuries. Numerous materials can be used to make it, including but not limited to the following:

Animal hides (hoofs and horns)

Suede (a type of leather derived from sheep or goat skin)

Plastic

Several methods are used to make leather goods; however, these all follow similar steps. First, we must prepare our raw material by removing hairs or dirt particles from its surface.

Next, we’ll need to cleanse it with soap and water so that there won’t be any bacteria growing on our product during processing, as well as make sure there aren’t any chemicals present in our material either!

After cleaning properly, we move onto the pre-tanning step, where chemicals like creams are applied onto these surfaces, causing them to become darker in color, so they’ll give off a more attractive appearance when finished up later on down the line, such as making apparel items like original leather jackets.

The next step is for the jacket to be cut and sewn.

The cutting process involves cutting out patterns, which will become the lining of our jacket. This is done using a rotary cutter, shears, or scissors if we have them on hand.

We may also use rulers or tape measurers to track where we’ve reached concerning our lines while designing the shape of our garment.

If necessary, ensure that whatever tool we’re using fits comfortably in one hand while holding it against the fabric so that it doesn’t slip out of control during this process.

Once all measurements have been taken from both sides of each piece separately (i.e., front/back), they should be transferred onto graph paper, after that they’ll be cut out using scissors.

Rotary cutter, depending upon how large/small each piece needs to fit together perfectly with another piece without becoming too bulky due its size being larger than usual standards set forth by fashion designers at high-end stores like Nordstroms and many others.

Embroidery decorates fabric or other materials with a needle, thread, yarn, or other materials. It may also incorporate other techniques such as cutting, quilting, and appliqué.

The embroidery can be done using thread types such as silk gauze or cotton braid and backing cloth on an embroidered piece. The design should not be too complicated because it will take more time to complete this process.

The final stage of the jacket-making process is quality control. This is an important step that ensures that all parts of the garment are fit for purpose and will last as long as possible.

Quality control is vital to ensuring our customers receive best leather jackets, so a quality control department must be in place to monitor this process. We may also consider hiring a QC manager with specific qualifications or experience in manufacturing clothing items such as suits, jackets, and shirts.

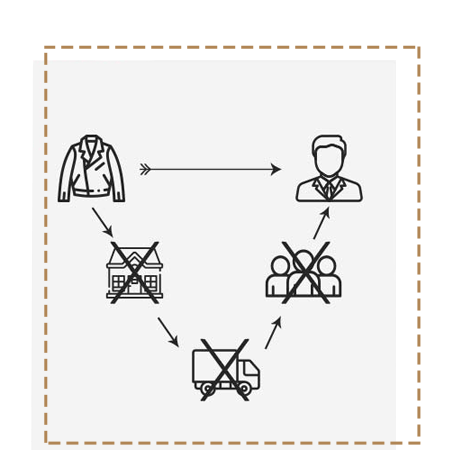

Our products are crafted with maximum efficiency and delivered directly to our customers without the involvement of middlemen. This enables us to make our products available at the fairest price that is a fraction of what other luxury brands would sell them for.